Many industries involve handling large quantities of liquids to create their products, the food industry being no exception. Distilleries and dairy processing factories use large quantities of raw liquid and create liquid waste that needs to be disposed of. Because of this, planning and selection of piping and liquid storage units are critical for the successful operation of these kinds of industries.

Advancements in pressure optimization and regulation are important for a more efficient and cost-effective workplace.

Finding an Alternative Source of Energy from Excess Water Pressure

Much of the food industry needs large quantities of water for its processes. Examples like the dairy and distillery sectors have both large inputs and outputs of water during production.

One problem with pipelines is the creation of excess pressure within the pipes, which could cause leaks and damage to the network if left unhandled. The usual solution to relieve the excess pressure would be to use pressure-reducing valves (PRVs). However, FullCycle Climate Partners, a growth equity fund that invests in to-scale climate-critical technology, may have found an innovative solution to this problem. They have recently invested in a micro-hydro technology company called InPipe Energy, whose goal is to harvest excess pressure from municipal water pipelines using their easily implemented In-PRV (pressure recovery valve) technology. Their technology also allows more precise pressure management, which leads to less water loss and protecting pipes from damage. Not only would this help remove the excess pressure in the pipelines, but it would also use this pressure to create renewable energy, which can then be reused for other operations, promising a rapid return of investment.

With the increasing need for energy combined with the looming threat of climate change, finding additional sources of renewable clean energy are crucial for business operations’ present and future success. By taking what was previously unused potential, such as excess pressure, and converting it to renewable energy is a groundbreaking and potentially cost-saving move for those in the businesses that handle much water distribution. In addition, other industries that also use a lot of pipe networks may want to investigate these kinds of technologies to create a more cost-saving and efficient operation.

Magnetic Flow Meters and the Pharmaceutical Industry

With the importance of efficient and maintained pipeline networks, the demand for devices that automatically monitor pipe flow has only increased. One such device is the flow meter, which measures the volumetric flow of liquids, from which it can calculate the absolute and differential pressure in the liquid. In 2021, the flow meter market was estimated to be around USD 7.7 billion, with a projected change to USD 10.3 billion in 2026. The primary industries that use flow meters were found to be the water and wastewater industries, as they could be used in numerous parts of water and wastewater treatment, with the requirement of clean discharge of effluents.

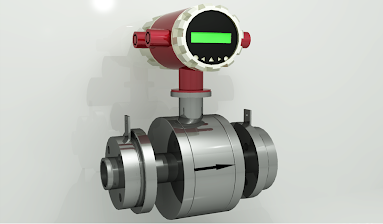

From market research in 2020, it was found that magnetic flow meters, or magmeters, were the most widely used type of flow meter. Using electromagnetic induction, magmeters were shown to be used in food and beverage industries for their ability to be unaffected by changes in water characteristics such as concentration, density, temperature, viscosity, and electrical conductivity.

A magnetic flow meter, also known as an electromagnetic flow meter.

While other industries have embraced the use of magnetic flow meters, the pharmaceutical industry has been having problems with the usual types of flow meters. Due to their use of ultrapure water, magnetic flow meters were not an option for precise measurement due to the very low conductivity of the liquid. To solve this problem, Bürkert developed a flow meter called FLOWave that uses surface acoustic waves technology. This device has no direct contact with the liquid it is measuring and solves other issues that flow meters encounter, such as system vibrations and conductivity of the liquid, to name a few.

Proper knowledge and maintenance of your pipe networks are essential for an efficient workflow. In addition, new advancements in the industrial sector make it best to keep updated on the latest news and technologies.

https://www.iqsdirectory.com/articles/flow-meter/magnetic-flow-meter.html

About the author: John Hamlin is a freelance writer who has a background in engineering. With a keen interest in technology and writing, John has been working online providing insight and direction for many years. His latest work has been on a compilation of industrial manufacturing techniques.

Print this page